A Guidance of Vehicle Braking Systems

Stepping on the gas is so simple that everyone knows how, but compared to acceleration, deceleration becomes a more advanced discipline. Whether it’s the track or the street in general, drivers have different requirements for brake braking, and the requirements for brake braking components are completely different. What is the brake braking system all about? How should I choose to upgrade the components? The following article will provide a very detailed introduction of braking systems.

Friction

When we press the brake pedal, the car will naturally slow down and stop, but why can a little bit of not too strong pedal action make a ton of car slow down and stop? In fact, the key point is through the role of “friction”.

Broadly speaking, as long as the opposite direction of motion is made on the contact surface, that is, the resistance, and the key is the pressure between the contact surface, which determines the size of the friction force. The principle of brake calipers is very simple, as long as the pressure is given, the brake disc will rotate slower, and together with the rotating wheel, the car will be braked to a stop, which is the source of the braking force.

In addition to the pressure applied, the “coefficient of friction” also determines the force of friction on the brakes because of the different materials, which is why when we choose different grades of brake discs and pads, they can also play a vital role in the braking system.

Disc Brakes

The common types of brakes are disc brakes and drum brakes. Compared to disc brakes, drum brakes have the advantages of taking up less space and being better enclosed. But the disadvantages are also very obvious, such as slow braking force response, poor heat dissipation and maintenance trouble. Therefore, there are fewer and fewer drum brakes on the market.

Disc brakes are the mainstream braking products in the market. The process of disc brakes is very simple: the piston in the caliper pushes the brake pad to clamp the brake disc in motion, and the piston’s pressurized force comes from the Pascal principle generated by the master pump.

At present, single-piston calipers are the standard for civilian cars, which simply means that a single piston pushes the brake pads on both sides to clamp the brake disc to stop the vehicle, but its disadvantage is obvious, that is, the average clamping force and rigidity are insufficient.

System Composition

1. Control system: pedal, handbrake, etc.

2. hydraulic system: composed of hydraulic oil, brake pump, hydraulic oil pipe.

3. Assistance system: vacuum assistance pump.

4. electronic control system: consists of ABS pump, ABS sensor, ABS computer.

5. Execution system: consists of brake calipers, brake pads, brake discs.

Operation flow

Foot on the brake pedal —- pedal force through the vacuum booster for amplified conduction —- amplified force to push the brake master cylinder, the brake fluid pressure —– brake fluid through the brake combination valve distribution to the front and rear wheel brakes, while the brake warning light comes on —– front and rear wheel brakes brake common tire brakes are divided into drum brakes and disc brakes.

Drum brakes mainly use brake fluid to push the friction pads to rub against the brake drum to apply the brakes. Disc brakes mainly use brake fluid to push the brake caliper to contract and compress the friction of the brake disc to apply the brakes.

Heat Dissipation

For brake braking system, heat dissipation is undoubtedly an important attribute that major manufacturers invest in research and development. The propagation of heat energy will lead to a gradual increase in the temperature of brake pads and discs, and overheating will naturally trigger a heat recession effect, which will infinitely reduce the braking force and even make the brakes fail. Therefore, butterfly brake discs will have many different design features, such as hollow, perforated, scribed and other designs that use air cooling to cool the car while driving, and some well-designed brake sets tend to put a lot of effort into cooling.

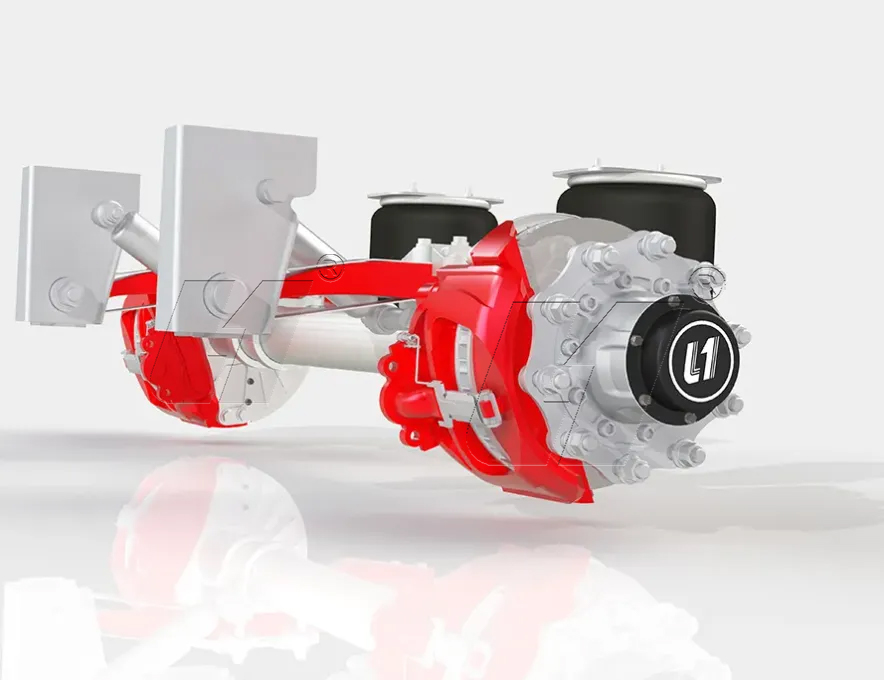

Yonglitai is a professional manufacturer of axles, bogies and suspensions, we have been in the machinery industry for 50 years and we are one of the largest manufacturers of semi-trailer axles in China. If you need to buy disc brake axle, welcome to contact us.