How Many Types of Axles Are There?

An axle is the rod or shaft that makes the wheels rotate and supports the weight of the vehicle. Axles are a fundamental part of any vehicle and are divided into three main types: front axles, rear axles and stub axles. Let’s break down the types of axles and see how to choose the right axle speed ratio for your vehicle.

Types of axles

According to Quadratec, there are three standard types of axles.

Rear axle: This axle is responsible for transmitting power to the drive wheels. It is divided into two halves, called half-axles, which are connected by differentials. In most cases, the rear axles are electrically charged, which means that they rotate with the wheels.

Front axles: Located at the front of the vehicle, they are responsible for assisting in steering and handling impacts from uneven surfaces. They have four main parts, namely the crossmember, the swivel pin, the track bar and the short axle. The front axles must be as strong as possible, which is why they are usually made of carbon or nickel steel.

Stub Axle: Stub axles are attached to the vehicle’s front wheels, with kingpins connecting these axles to the front axle.

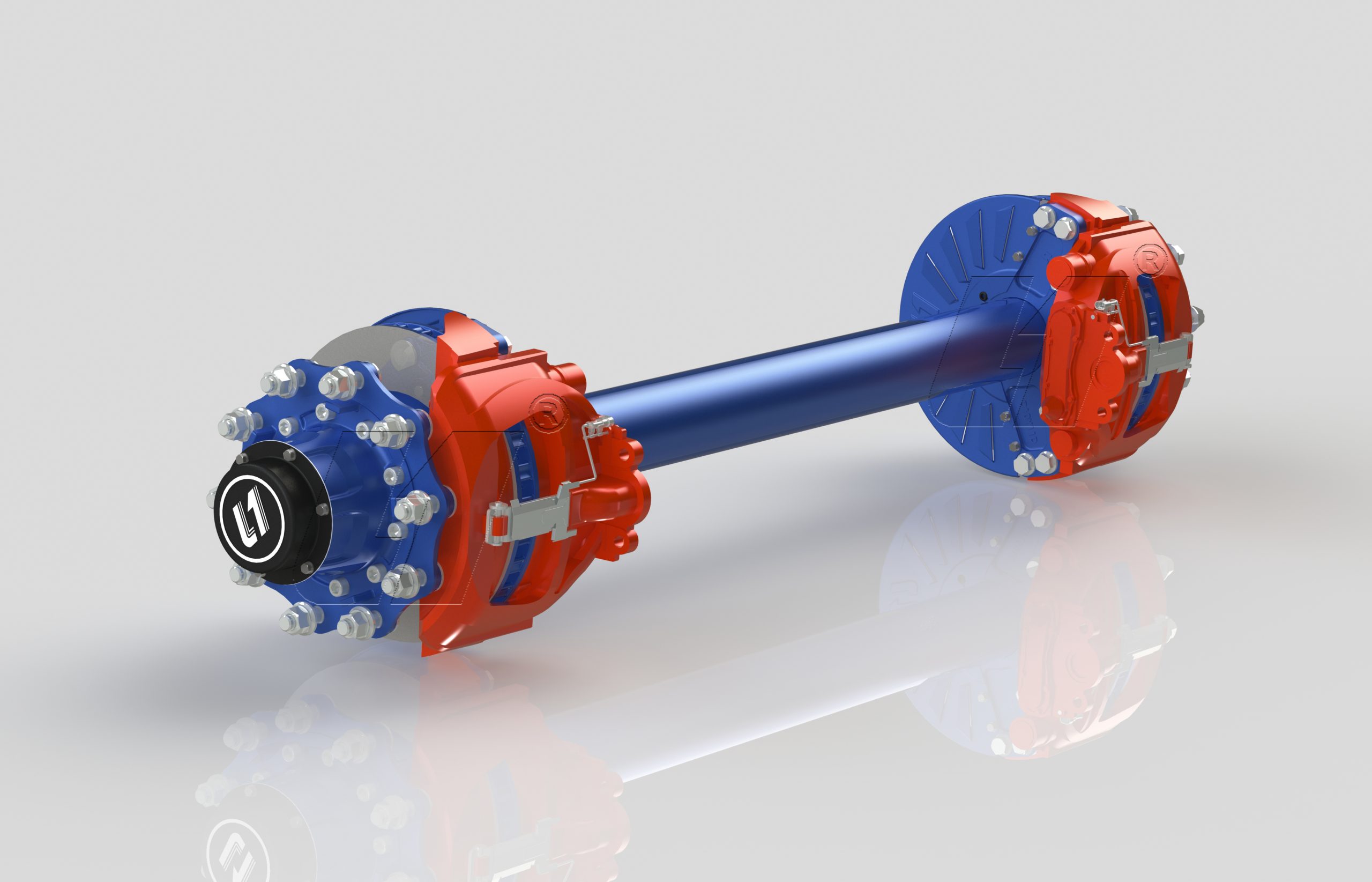

Disc Brake Wheel Axle For Semi Trailer

Rear Axle Types

Not all rear axles are the same, as the method of support and mounting determines the type. According to The Engineers Post, there are three types of rear axles.

Semi-floating axle: This rear axle attaches the wheel to a flange on the outside of the half-axle and holds it securely in place. One bearing supports the half-shaft and the other bearing is inside the axle housing. Because it has two bearings, the semi-floating axle needs to be larger than the other options to produce the same amount of torque. Semi-floating axles are used in cars, SUVs and medium duty trucks such as half tons and light pickups.

Full floating axle: As the name implies, this axle type effectively floats in place and holds its position thanks to two bearings. It is designed to transmit only the drive torque. Fully floating axles tend to be best suited for larger vehicles, such as heavy trucks. Some medium-duty trucks with greater towing capacity or trucks with extensive use of four-wheel drive can also benefit from a fully floating axle.

Three-quarter floating axle: It is more complex and more reliable than a semi-floating axle. It helps maintain wheel alignment and handles lateral thrust and drive torque.

Board Axle For Goods Train

Types of front axles

According to Meineke, there are two main types of front axles for vehicles. These are

Dead front axles: These axles are fixed in place and do not rotate with the wheels. Most dead front axles and differentials have housings that prevent them from coming into contact with water or dust.

Live Front Axle: Unlike dead front axles, live front axles deliver driving power from the gearbox to the front wheels.

Types of Stub Axles

As explained by The Engineers Post, there are four types of the stub axle.

Elliot: This type uses a main kingpin, a yoke and an opening to connect to the front axle.

Reverse Elliot: This type has the opposite arrangement of the standard Elliot stub shaft.

Lamoine: This short axle type has an L-shaped spindle instead of a yoke hinge.

Reverse Lamoine: It has the opposite layout to the standard Lamoine stub axis.

Choose Yonglitai ‘s types of axle systems to stop your trailer or fifth wheel safely. Turn to Yonglitai for professional installation recommendations and technical support. If you have another question, getting in touch with us.